Vo2Max and Heart Health – A Single Ride Following Dr. Paddy Barrett’s Formula

Vo2Max and Heart Health Correlation With DFAA-1 and other Metrics I recently stumbled across a Substack post by Dr. Paddy Barrett that explains how Vo2Max is impacted by low intensity exercise. While I had not known about Dr. Barrett previously, when I read his history and other posts, I became intrigued. I think he’s a […]

The OBC Dicta

The OBC Dicta (or, The Nine Commandments for Peak Performance In Cycling). *** I wrote the first version of this over twenty years ago, hoping that it would become the foundation for another book, but life and acceleration got in the way, and I just found it again in my Google Drive. A ‘Dicta‘ is […]

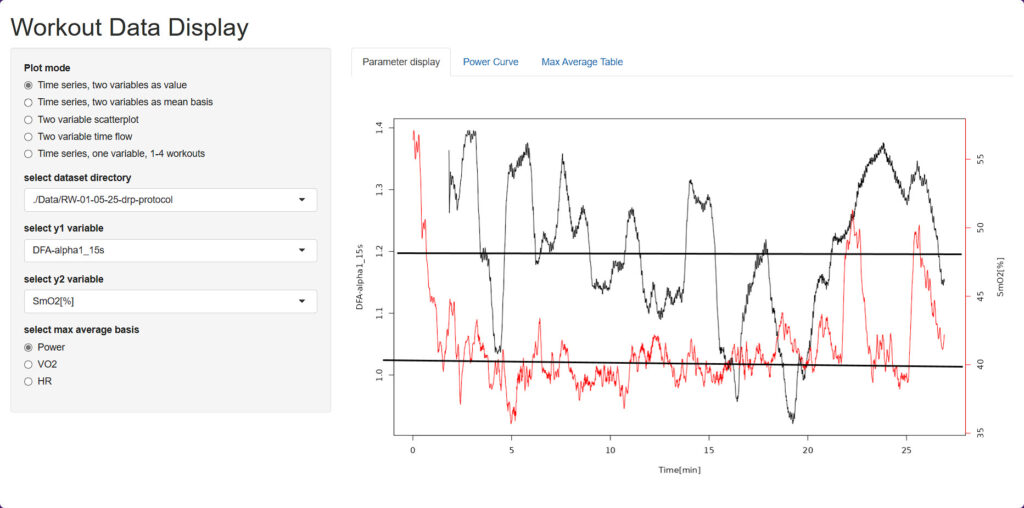

The Physiological Perspective of Four Separate 8-Minute Intervals

8-Minute Intervals At “Threshold”… In late November of 2024, I was able to perform an interval session on my indoor trainer and bike with my clients. The workout comprised of four separate 8-minute intervals. We used the VQ Velocity app, and I recorded each interval as a separate file while wearing my Vo2Master Gas Exchange […]

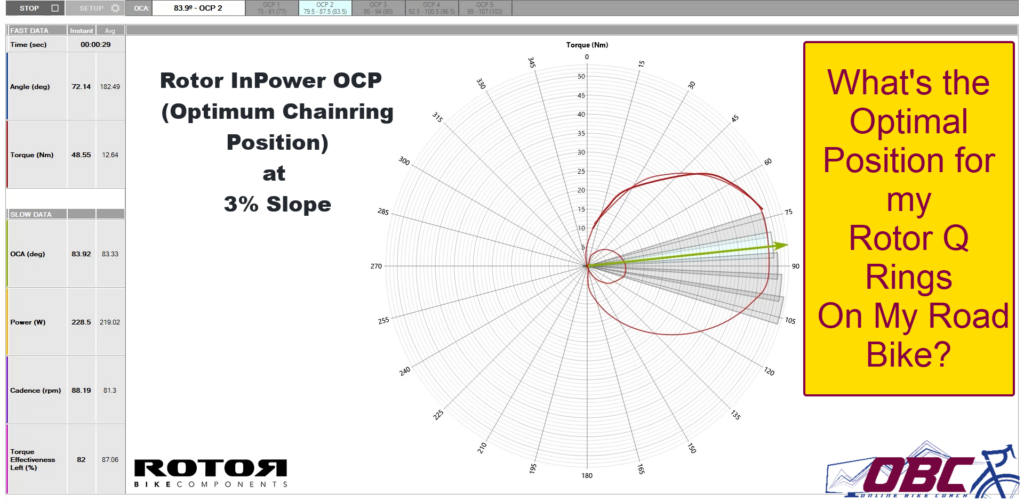

Rotor Q Rings Revisited – Yet Again

Rotor Q Rings DO Work – Just Not The Way You Might Think I’ve been using Rotor Q Rings ever since they came out. Prior to that, I was using Rotor’s ‘RSX’ technology, because the company gave their product to trained scientists for honest review and application. The theory behind Q rings is that they […]

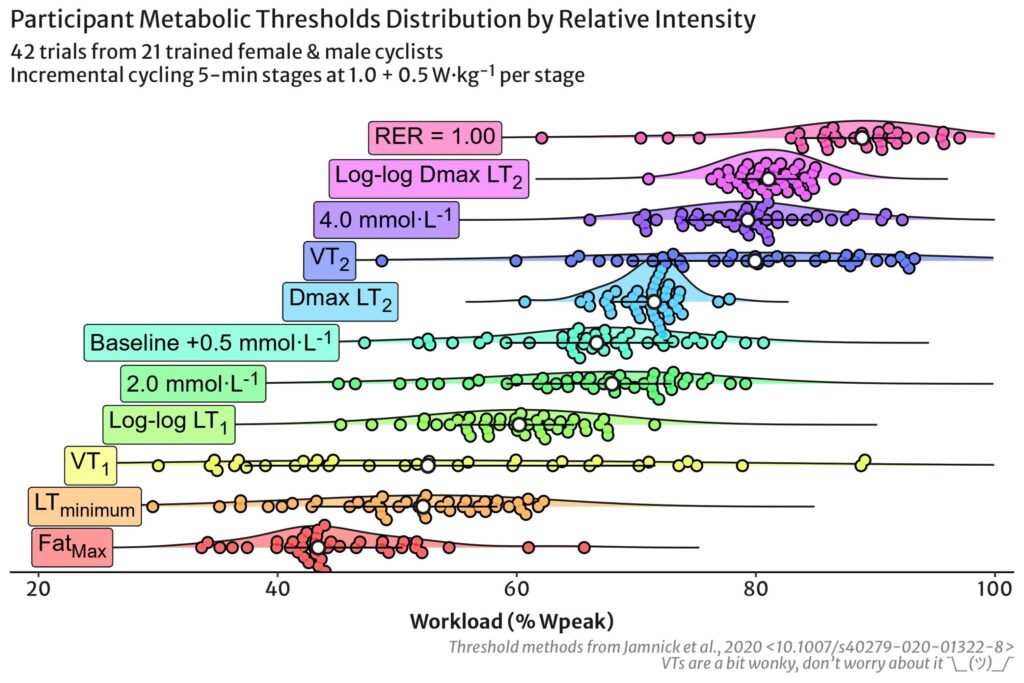

Vo2 at Threshold

Vo2 at Threshold – Affirming Outdoor Power at Threshold In my last blog post, I mentioned that for my best 10-minute effort while climbing a trail on a mountain bike, my Vo2 at Threshold read as roughly 55ml/kg/min. I also believed that my Vo2Max was roughly 62ml/kg/min. I was curious to see if these values […]

Vo2Master Vo2Max Value Affirms Garmin Vo2Max Estimator

Vo2Master’s Vo2Max Value Was 98% Consistent with Garmin In May of this year, I wrote a post about the Garmin Vo2Max Calculator. In July, I was able to test my Vo2Max at OBC Headquarters, to compare values. I performed a Graded Exercise Test, using the Vo2Master app. This app, on a cell phone, trapped data […]

Return to Reno!

Return to Reno – Fresh Air, Open Roads, Singletrack and Jeep Trail out the Front Door. Hey everyone – Rich here, writing from my home studio in Reno, Nevada. After 18+ long months where my wife, dogs and I left Reno, moved to Pueblo, CO, realized it was a wrong move, and then moved all […]

More Fun With Garmin EPOC

Garmin EPOC – A definition Since restarting regular training in February, I’ve come to enjoy the Garmin Connect Ecosystem and Garmin EPOC. EPOC is an acronym that stands for: “Excess Post-Exercise Oxygen Consumption”. It means this: When you exercise, you burn fat and carbs. The ratios of fat and carbs burned for fuel, depend on […]

Covid-19 and the Garmin Sleep Stress Score

A Family Member Caught Covid-19 and the Garmin Sleep-Time Stress Score Is Pretty Scary Three and a half years after Covid-19 spread around the world and began infecting humans, a family member finally caught Covid-19, and their Garmin Sleep-Time Stress Score is pretty scary. Sleep-Time Stress uses Heart Rate Variability (or the lack thereof) to […]

Bike Fit With AthletiCamps’ Bruce Hendler

A Good Bike Fit is MORE Important Than a Good Bike! Most of you know how much I believe in a good bike fit. When I ran my studios in North Texas, I actively recruited Craig Fulk of Dynamic Bike Fit, to place a small studio in my East Dallas location. Later, when he opened […]